Delivering leading food safety and industrial X-ray inspection systems.

Our solutions integrate seamlessly with your production to ensure efficiency and confidence.

Delivering leading food safety and industrial X-ray inspection systems.

Our solutions integrate seamlessly with your production to ensure efficiency and confidence.

Trusted by the world leaders in manufacturing and production

Trusted by the world leaders in manufacturing and production

The Industries we Serve

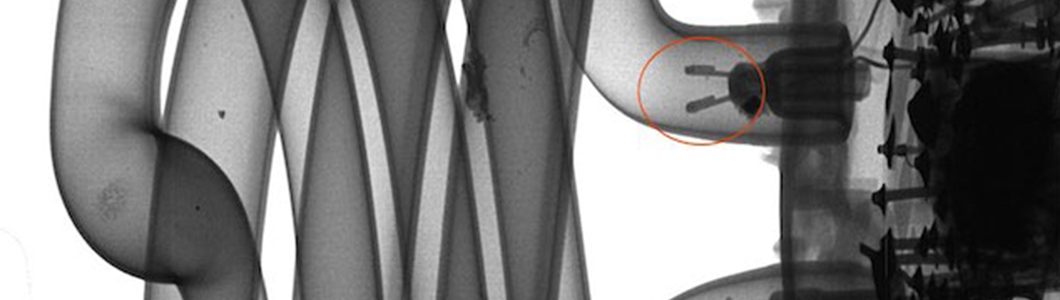

Our x-ray systems are designed, engineered, and validated through our longstanding relationship with industry partners. Kodex executes the precision and accuracy needed no mater what the industry or inspection needs.

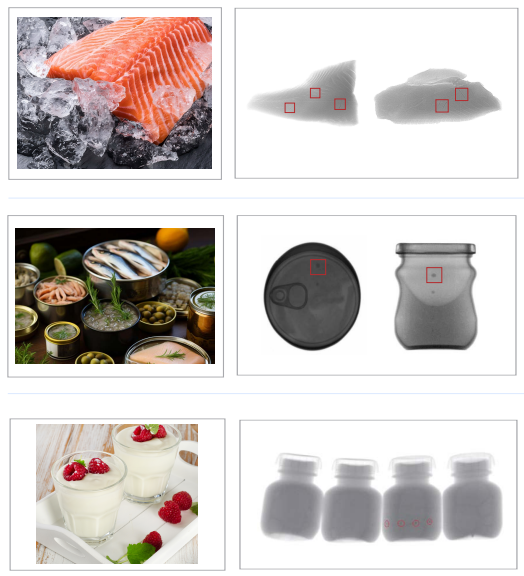

Food & Beverage

The food industry requires dynamic adaptability and flexible execution. We offer solutions ready to be implemented in any environment of phase of production, offering our global customers the ability to ensure consistent inspections with any product type.

TruView™ 4015N

Delivers precise detection of foreign matter in small, lightweight packaged foods, including confectionery, meat, vegetables, noodles, biscuits, jerky, and nuts. Designed for the food industry, the system ensures product safety, quality assurance, and compliance with international standards.

TruView™ 6030-N

Designed to detect foreign matter contaminants in large packaged and boxed food products. The system delivers accurate, high-throughput inspection to protect product quality, enhance consumer safety, and ensure compliance with stringent food industry standards.

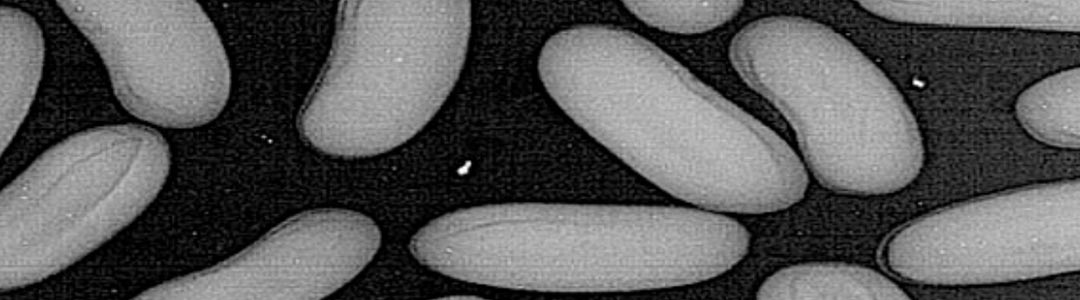

TruView™ 6010-B

Engineered for the detection of foreign matter contaminants in bulk materials and other large-volume products. The system provides reliable, high-sensitivity inspection to safeguard product purity, ensure consumer safety, and support regulatory compliance across diverse industries.

TruView™ 1830

Engineered for the detection of foreign matter contaminants in bottled food products and similar packaged goods. The system ensures precise, high-speed inspection to maintain product integrity, protect consumer safety, and meet rigorous food industry standards.

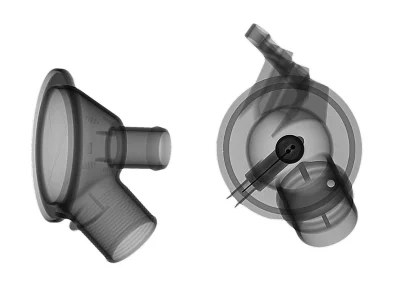

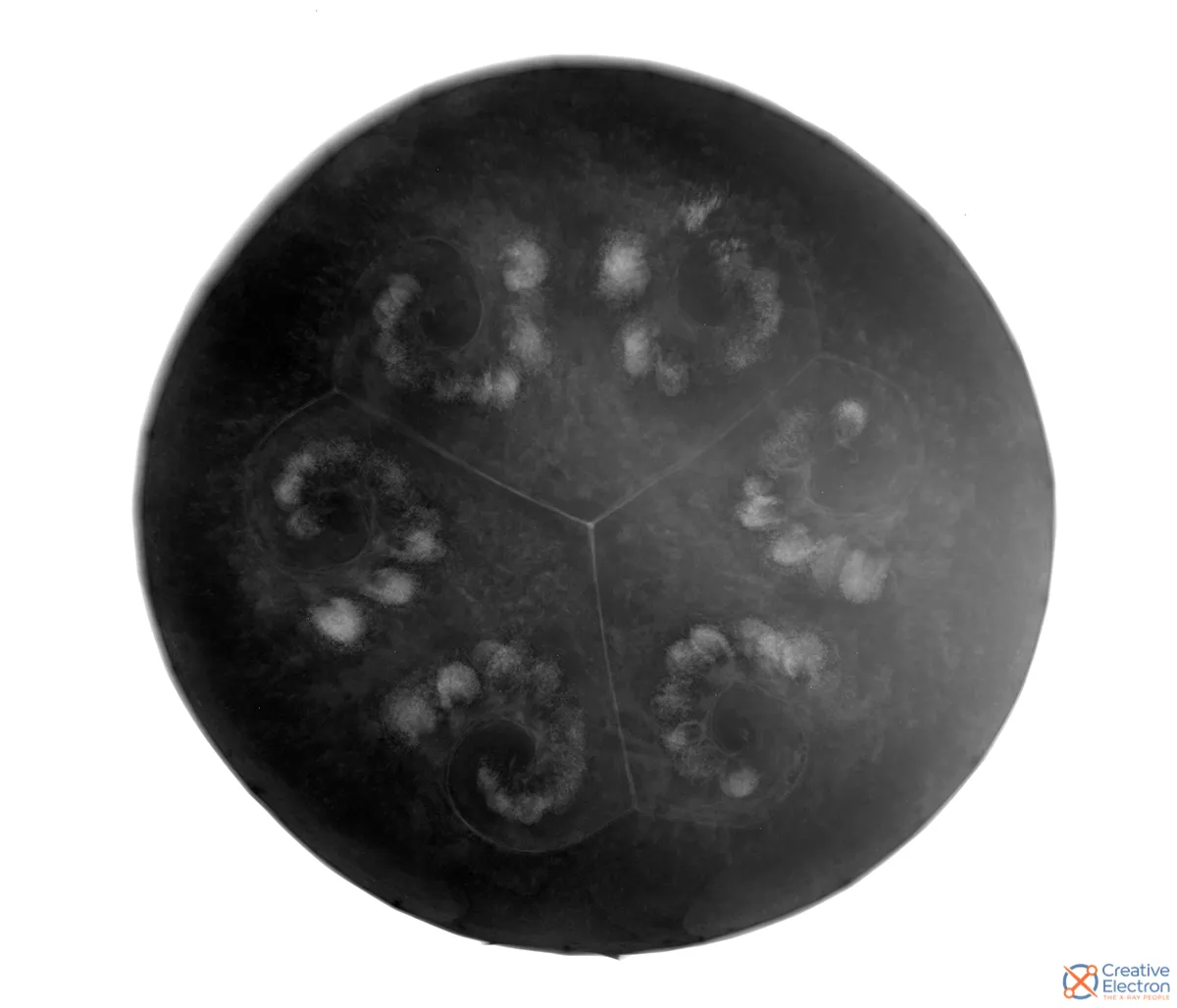

TruView™ 160

Primarily utilized for non-destructive testing across a wide range of applications, including metal castings, hardware components, plastic products, refractory and resin materials, review samples, ceramic bodies, and welded metal parts. The system is especially suited for inspecting small and micro-sized products with precision and reliability.

TruView™ 160 XL

Widely utilized for the inspection of small to medium-sized products, including metal castings, welded components, hardware, plastics, rubber, refractory and resin materials, composite structures, and ceramic bodies. The system serves a broad range of industries such as equipment manufacturing, electronics, automotive, and high-speed rail, delivering reliable non-destructive testing solutions with precision and efficiency.

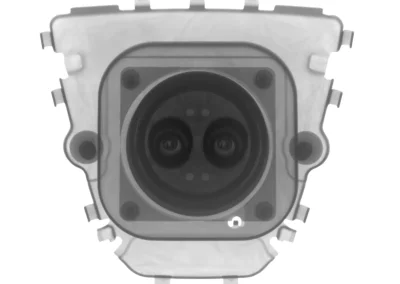

TruView™ 320

Designed for the inspection of various castings, including aluminum, iron, and other alloys. The system provides non-destructive testing (NDT) to detect air bubbles, porosity, and foreign material inclusions. It is well-suited for the examination of automotive components, steel pipes, cylinders, and pressure vessels, ensuring structural integrity and product reliability.

TruView™ 450

Engineered for non-destructive testing (NDT) of aluminum castings, ductile iron, and automotive components. The system accurately detects porosity, gas bubbles, and foreign material inclusions, ensuring product quality and reliability.

TruView™ 225

For the non-destructive testing of castings to identify air bubbles, porosity, and foreign material inclusions. The system is also designed for detecting welding defects in cylinders, as well as flaws such as slag inclusions, cracks, looseness, and structural irregularities in components including tire steel cords and belts, hubs, pressure vessels, refractory materials, bullets, boilers, and both welded and seamless pipes. Offering high sensitivity and reliability, it ensures superior quality assurance across demanding industrial applications.